10 rules for a successful ERP project

At any moment, we have a number of ERP projects going. We decided to review all our recent ones to...

Read moreAt any moment, we have a number of ERP projects going. We decided to review all our recent ones to...

Read moreAt the centre of your business where People, Process, Data and Technology meet are your systems. Larger businesses will have...

Read moreAn Enterprise Resource Planning (ERP) project is when you integrate all your company’s core processes into a single system, finance,...

Read moreAn Enterprise Resource Planning (ERP) project is when you integrate all your company’s core processes into a single system—finance, HR,...

Read moreAn Enterprise Resource Planning (ERP) project is when you integrate all your company’s core processes into a single system—finance, HR,...

Read moreExcel is incredibly popular, and with good reason: it's cheap, it's useful, and it's easy to use. You still shouldn't...

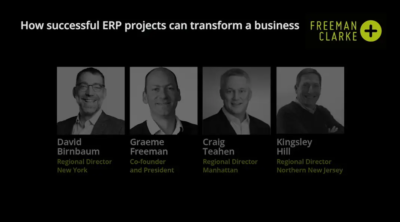

Read moreWe’ve recorded a series of discussions with our ERP experts: Regional Director Christine Parker, Our Co-founder and director Graeme Freeman...

Read morePrivate Equity (PE) ownership of mid-market companies is increasing. Of course, PE investors are driven by valuations, and these days...

Read moreThis is the second in a two-part series on how to launch a successful Enterprise Planning Resource (ERP) project. For...

Read morePlain English board-level briefings focused on technology strategies to deliver competitive advantage and business success.

You can unsubscribe at any time.

Call us on 0203 020 1864 with any questions.

Graeme Freeman

Co-Founder and Director

Plain English board-level briefings focused on technology strategies to deliver competitive advantage and business success.

You can unsubscribe at any time.

Call us on 0203 020 1864 with any questions.